At Auglaize Erie Machine, we build solutions. As a leading precision CNC machine shop, we combine skilled craftsmanship with the right technology to deliver components that fit, function, and perform exactly as needed. Whether you need tight-tolerance machining, fabrication, or finishing, we’ve got the expertise and equipment to get it done right.

Capabilities

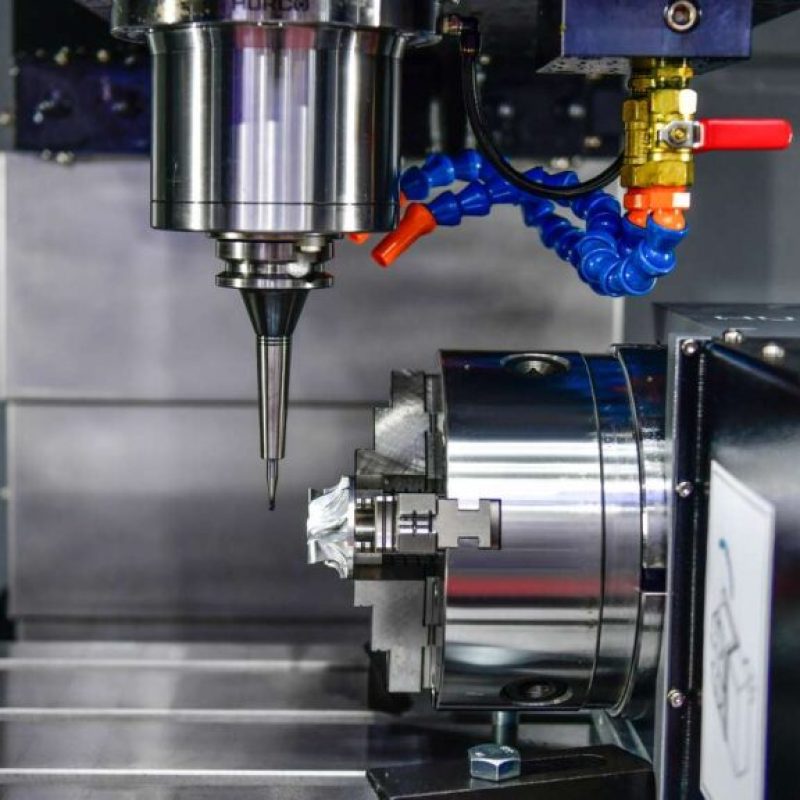

CNC Machining

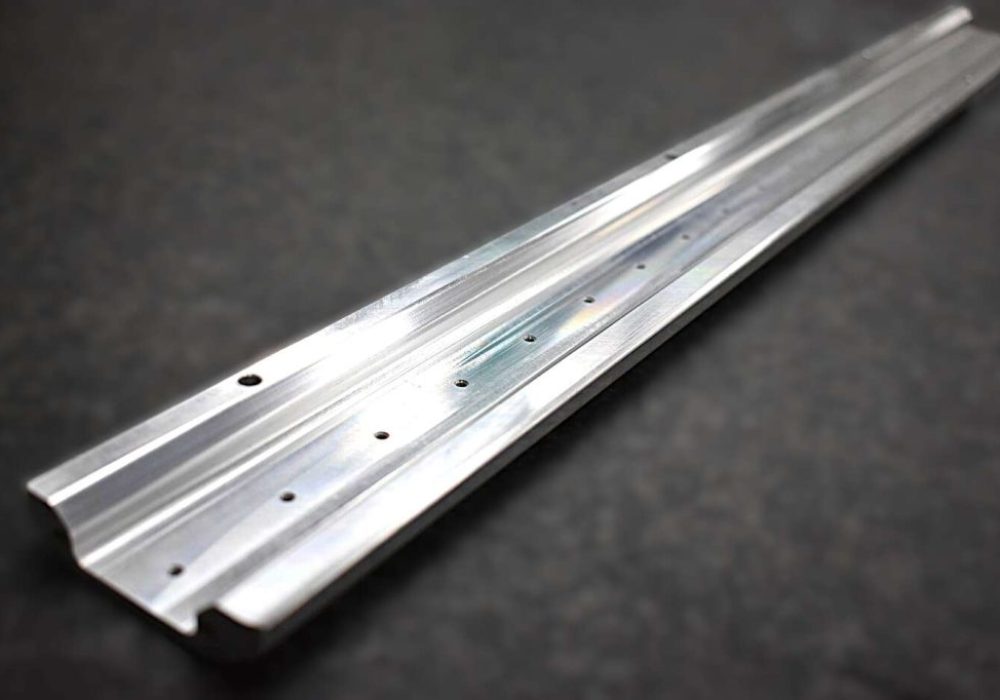

Our CNC machining services cover everything from prototyping to full production runs. We work with a variety of materials, including steel, aluminum, brass, and plastics, turning raw stock into finished parts with tight tolerances. With multi-axis machining centers, we handle complex geometries and intricate details without missing a beat.

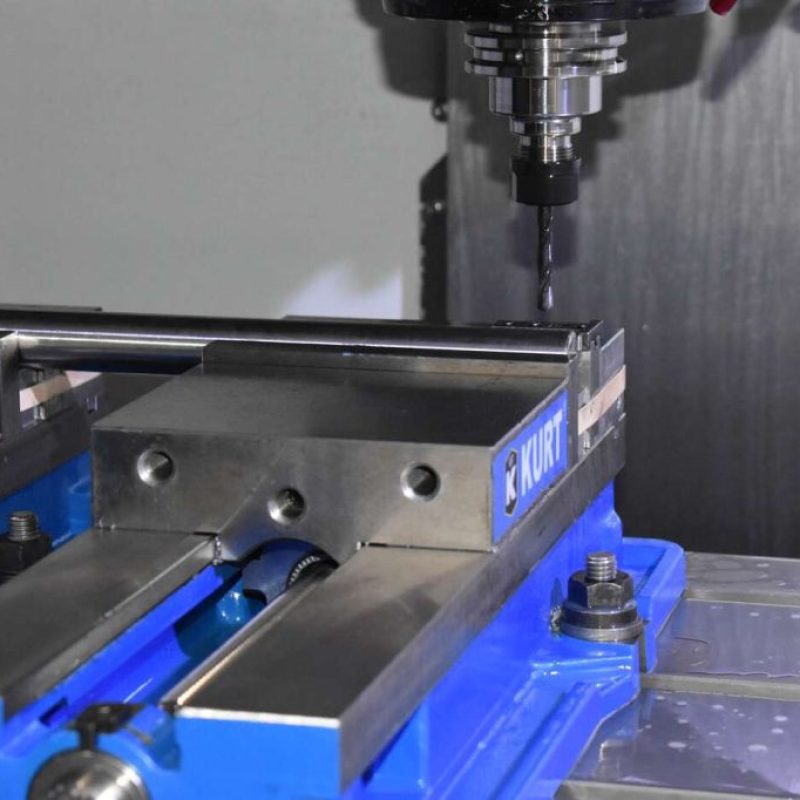

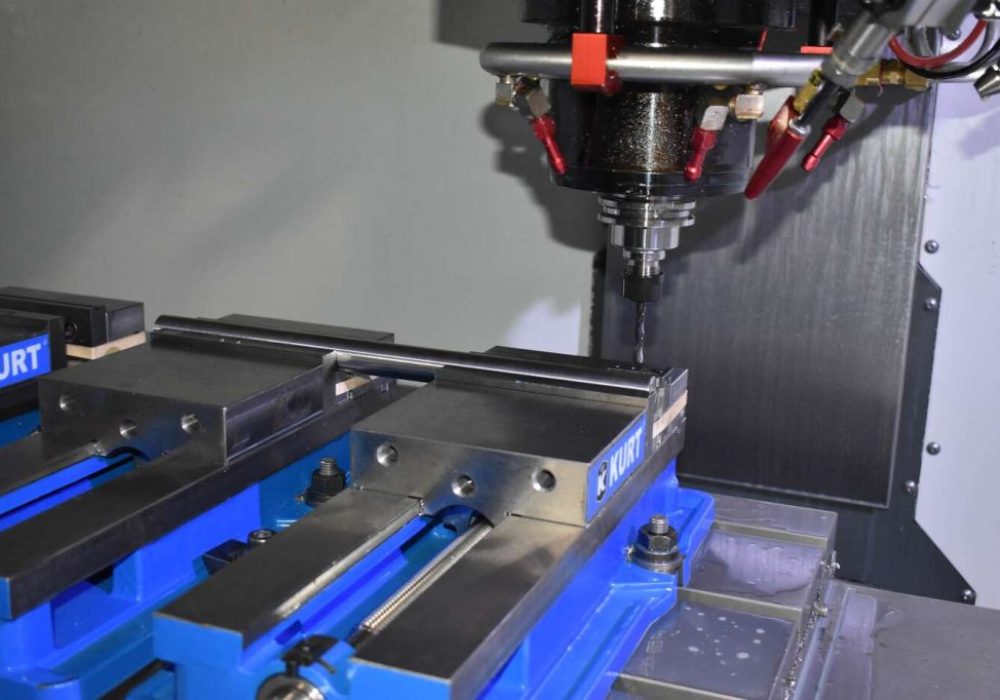

Milling & Turning

From simple brackets to high-volume shafts, our milling and turning capabilities ensure parts meet exact specifications. Our CNC lathes and mills handle both one-off jobs and repeat production, maintaining consistency across every batch. Need threaded holes, keyways, or contoured surfaces? We’ve got the tools for the job.

Fabrication & Welding

Not every project starts with a solid block of metal. Our fabrication and welding team shapes, bends, and joins materials to create strong, durable assemblies. Whether it’s laser-cut brackets, welded frames, or formed sheet metal, we build parts that hold up under real-world use.

Industries Served

Serving many industries and working with a wide range of materials and finishes, our facility offers the most advanced mills, lathes, and welding equipment to quickly fabricate the exact product you want, built to the most exacting specifications.

Quality

Inspection & Certifications

Quality is built into every step of our process. We use inspection equipment and optical comparators to verify dimensions, ensuring parts meet print specifications. Our team follows documented procedures, and we maintain certifications to prove our work meets industry standards.

Tolerances matter, and we hold them tight. Whether it’s a +/- 0.005” requirement or an even tighter callout, we measure, check, and double-check before anything leaves our shop.

About Us

Experience matters. With decades in the machining business, we’ve learned what works and what doesn’t. We don’t cut corners and we don’t overpromise. We just provide solid work, fair pricing and honest communication.

Success made simple. That has been our slogan and vision since 1978

Contact Us / RFQ

Ready to get started? Send us your prints and we’ll provide a fast, no-obligation quote. Whether you need one prototype or thousands of production parts, we’re here to help.

At Auglaize Erie Machine, we’re more than just a precision CNC machine shop. We’re a partner you can rely on. Let’s make something great together.